Preventing persistent microplastic formation is one of the most critical environmental challenges facing businesses today. When packaging escapes containment into the environment, traditional plastic can persist for decades as microplastics. BioBottles™ and BioCaps™ powered by PlasticIQ™ Technology provide packaging solutions that prevent persistent microplastic formation while maintaining full functionality.

The Microplastic Challenge

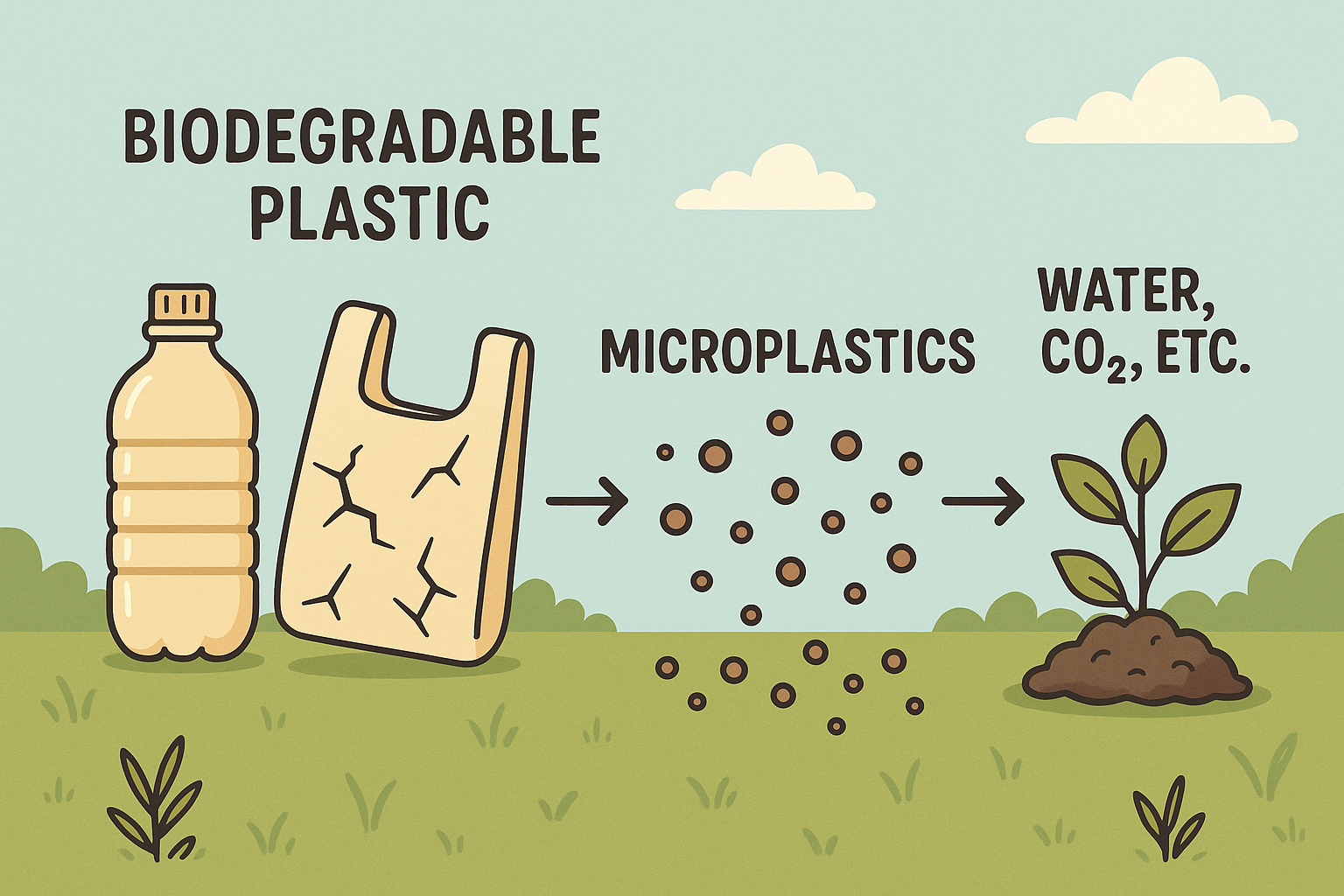

Only ~9% of global plastic waste is recycled; the rest enters landfills, incineration, or mismanaged disposal. When traditional plastic packaging escapes containment, it can degrade into microplastics that persist for decades. The European Chemicals Agency (ECHA) defines microplastics as persistent synthetic polymer fragments resistant to biodegradation, confirming their environmental persistence.

This persistence creates a fundamental challenge for businesses: how to maintain plastic's practical benefits while preventing persistent microplastic formation when packaging escapes containment. BioBottles™ solve this challenge by using PlasticIQ™ Technology—a chemical additive that prevents persistent microplastic formation.

How Packaging Solutions Prevent Microplastics

PlasticIQ™ is a chemical additive (not software or computer technology) that enables HDPE and PP to prevent persistent microplastic formation. When exposed to oxygen, UV light, and heat—conditions that occur when packaging escapes containment—the additive catalyzes controlled oxidation that reduces molecular weight below 5,000 Daltons, enabling microbial bioassimilation.

This process is scientifically verified under ASTM D6954 Tier 1-3 testing to prevent the formation of persistent microplastics. Independent laboratory validation confirms that BioBottles™ provide genuine environmental benefits by preventing persistent microplastic formation when packaging escapes containment.

The ASTM D6954 Verification Process

ASTM D6954-24 is the definitive test protocol for plastics designed to prevent persistent microplastic formation. It consists of three tiers that together verify the complete pathway from polymer to non-persistent material.

Tier 1: Abiotic Degradation - Confirms molecular weight reduction below 5,000 Daltons, the threshold for plastic persistence. BioBottles™ have demonstrated PE reduced to 2,200 Da and PP reduced to 4,900 Da.

Tier 2: Biodegradation - Confirms microbial assimilation of the oxidized material. Independent testing confirms 94.55% biodegradation for PE and 92.76% biodegradation for PP within 2 years.

Tier 3: Eco-toxicity - Confirms no harmful residues. Testing confirms no adverse effects on earthworms, Daphnia magna, seed germination, or soil organisms.

Why Scientific Verification Matters

Many packaging solutions claim to prevent microplastics, but scientific verification through ASTM D6954 testing provides independent laboratory validation. This verification gives businesses credible, science-based sustainability stories for their brands.

Without scientific verification, businesses risk making environmental claims that may not be supported by evidence. BioBottles™ provide independent laboratory validation through multiple testing facilities, ensuring packaging solutions meet genuine environmental standards for preventing persistent microplastic formation.

The Business Case for Preventing Microplastics

Beyond environmental considerations, packaging solutions that prevent persistent microplastic formation offer strategic business benefits. Companies that adopt such solutions can differentiate themselves in the market, demonstrating genuine environmental responsibility.

This differentiation matters for brand credibility. Consumers increasingly value brands that demonstrate environmental responsibility, and businesses that address microplastic concerns through their packaging choices can build stronger consumer trust. The verifiable, science-backed nature of BioBottles™ provides a measurable sustainability story.

Additionally, as research on microplastics advances, regulatory bodies may implement stricter requirements for packaging materials. Companies that transition to packaging solutions verified to prevent persistent microplastic formation position themselves ahead of potential regulatory changes, future-proofing their brands.

Implementation for Businesses

For businesses ready to adopt packaging solutions that prevent persistent microplastic formation, several factors should be evaluated. First, verify scientific claims through independent laboratory testing. BioBottles™ provide ASTM D6954 Tier 1-3 verification from multiple independent laboratories.

Second, assess performance during normal use. BioBottles™ maintain the same durability, shelf life, and functionality as standard HDPE and PP bottles. They work exactly like regular plastic bottles—no special equipment or handling required.

Third, consider regulatory compliance. BioBottles™ comply with FDA 21 CFR §177.1520 for food-contact applications and meet FTC Green Guides and California SB 343 requirements. This compliance support makes packaging solutions that prevent persistent microplastic formation a practical choice for businesses.

The Master Claim

The approved claim for BioBottles™ is: "Scientifically verified under ASTM D6954 Tier 1-3 testing to prevent the formation of persistent microplastics." This claim is supported by independent laboratory data demonstrating oxidative and biological breakdown without formation of persistent microplastic residues.

This master claim provides businesses with verifiable, science-based messaging for their brands. It meets regulatory requirements while providing credible environmental benefits that resonate with consumers and stakeholders.

Learn More

Interested in learning more about packaging solutions that prevent persistent microplastic formation? Contact us to discuss how BioBottles™ can meet your packaging needs. Explore our packaging solutions and scientific verification to understand how we can help your business prevent persistent microplastic formation.